QUALITY ASSURANCE

Built To Deliver

Our work stands the test of time. Our clients expect the best, and we deliver world-class products and services with a personal touch. With the right tools and people, Phoenix is redefining excellence in industrial innovation.

A Culture of Quality

Quality control is a major cornerstone of our service philosophy and business practice. It is Phoenix Group of Companies’ policy to consistently operate to the highest standards through the implementation of ISO 9001:2015 standards, including risk assessments at all phases as well as continual improvement efforts. Through decades of dedicated learning and experience, PGC has become one of Western Canada’s innovative leaders in industrial construction, maintenance, and fabrication.

Client Success

Taking pride in a job well done, we believe quality control is more than certifications and designations. Phoenix works closely with internal and external partners to ensure the work we do exceeds expectations in line with business objectives.

Consistent Quality

Phoenix has developed comprehensive, company-wide quality control systems that ensure our clients receive consistently exceptional products and services that meet and, where possible, exceed customer expectations.

Infield Support

Our skilled QC/QA specialists are available onsite throughout your project to ensure that all team members and project partners adhere to required safety and compliance standards. The Phoenix Quality department encourages the full involvement of employees in order to develop their abilities for the benefit of the individual and the company.

Certifications

Our commitment to quality is more than lip service. At PGC, we can back up every one of our standards with industry-recognized certifications that hold our team accountable to the highest standards of excellence.

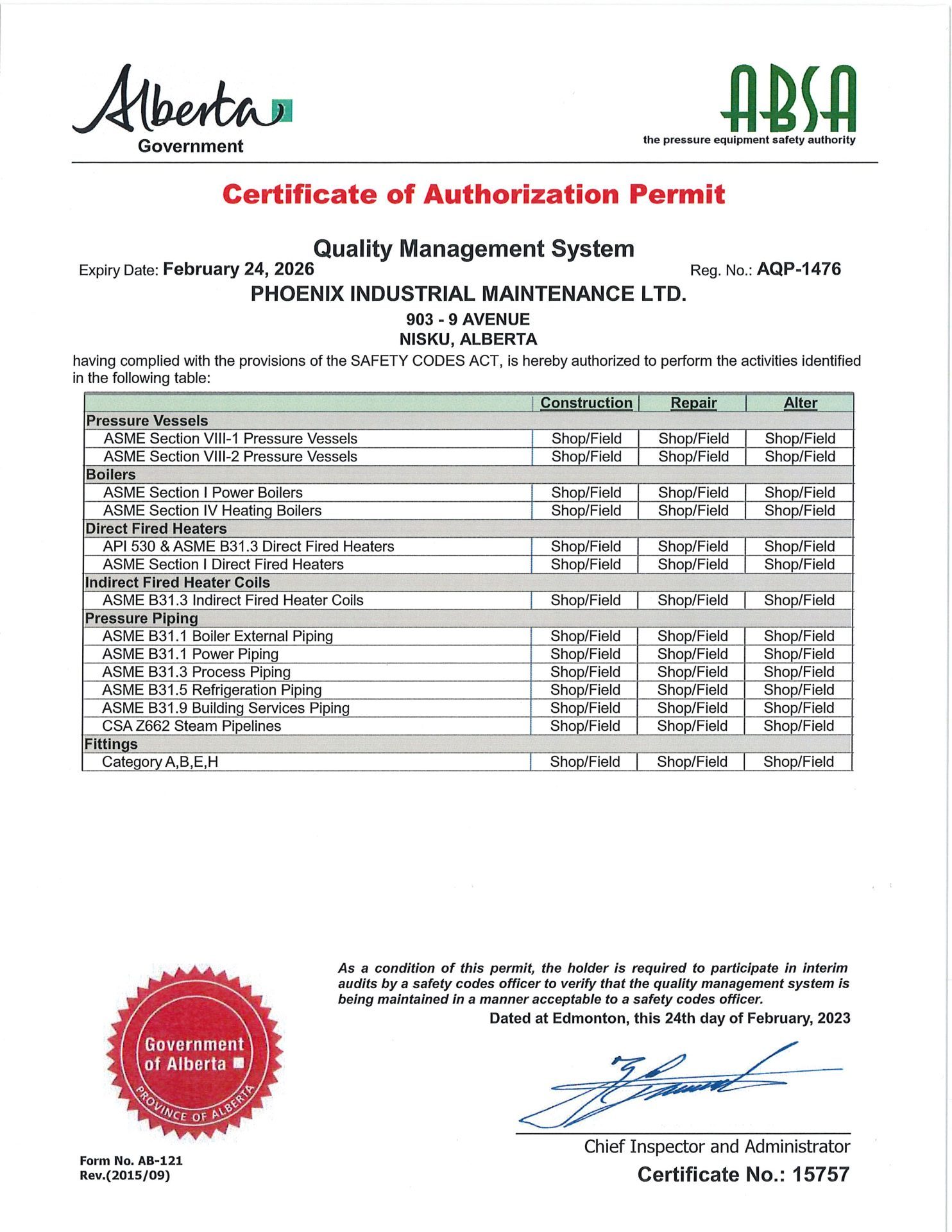

Our current Quality Control Program is registered under AQP-1476(S) with the Alberta Boiler Safety Association.

This program defines organizational and system requirements to ensure that all construction complies with all client specifications and governing codes.

Our quality certifications are highlighted below.

For Close Toggle Default

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

ABSA

- ABSA-AQP#1476, Certificate #16391

- ABSA-AOQP#7299, Certificate #16393

API / ASME / CSA

PRESSURE VESSELS

- ASME Section VIII-1 Pressure Vessels – Construct, Alter, Repair (Shop and Field)

- ASME Section VIII-2 Pressure Vessels– Construct, Alter, Repair (Shop and Field)

BOILERS

- ASME Section I Power Boilers – Construct, Alter, Repair (Shop and Field)

- ASME Section IV Heating Boilers – ALTER (Shop and Field) Construct, Alter, Repair (Shop and Field)

DIRECT FIRED HEATERS

- ASME Section I Direct Fired Heaters – Construct, Alter, Repair (Shop and Field)

- API 530 AND ASME B31.3 Direct Fired Heater – Construct, Alter, Repair (Shop and Field)

INDIRECT FIRED HEATERS

- ASME B31.3 Indirect Fired Heater Coils – Construct, Alter, Repair (Shop and Field)

PRESSURE PIPING

- ASME B31.1 Boiler External Piping – Construct, Alter, Repair (Shop and Field)

- ASME B31.1 Power Piping – Construct, Alter, Repair (Shop and Field)

- ASME B31.3 Process Piping – Construct, Alter, Repair (Shop and Field)

- ASME B31.5 Refrigeration Piping – Construct, Alter, Repair (Shop and Field)

- ASME B31.9 Building Services Piping – Construct, Alter, Repair (Shop and Field)

- CSA Z 662- Steam Pipelines – Construct, Alter, Repair (Shop and Field)

FITTINGS

- Category A, B, E H Construct, Alter, Repair (Shop and Field)

- Category C, F Alter, Repair (Shop and Field)

PERFORM HOT TAPPING (FIELD ONLY)

- API 530 AND ASME B31.3 Direct Fired Heater

- ASME B31.1 Boiler External Piping

- ASME B31.3 Process Piping

- ASME B31.5 Refrigeration Piping

- ASME B31.9 Building Services Piping

- ASME Section I Direct Fired Heater

- ASME Section VIII-1 Pressure Vessels

- CSA Z 662- Steam Pipelines

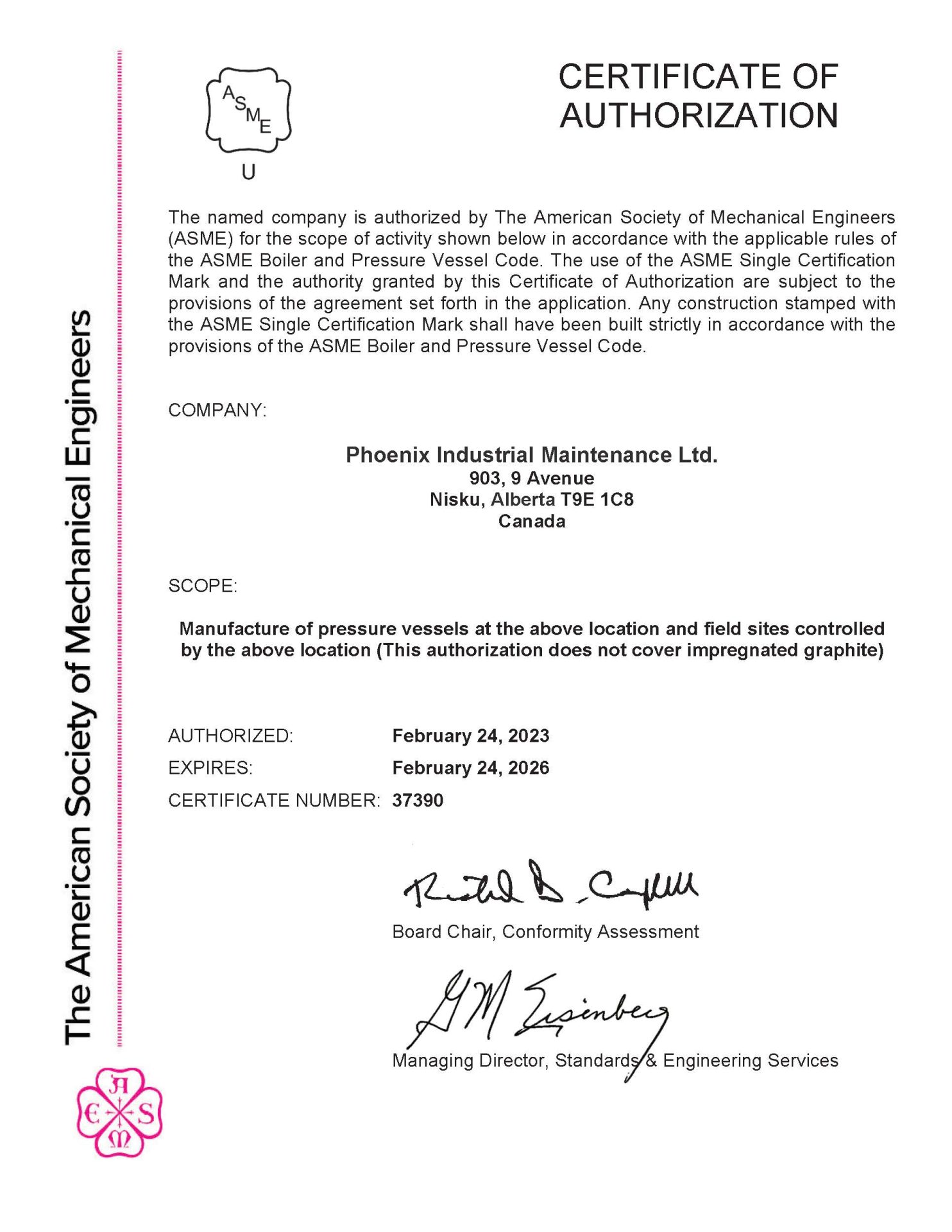

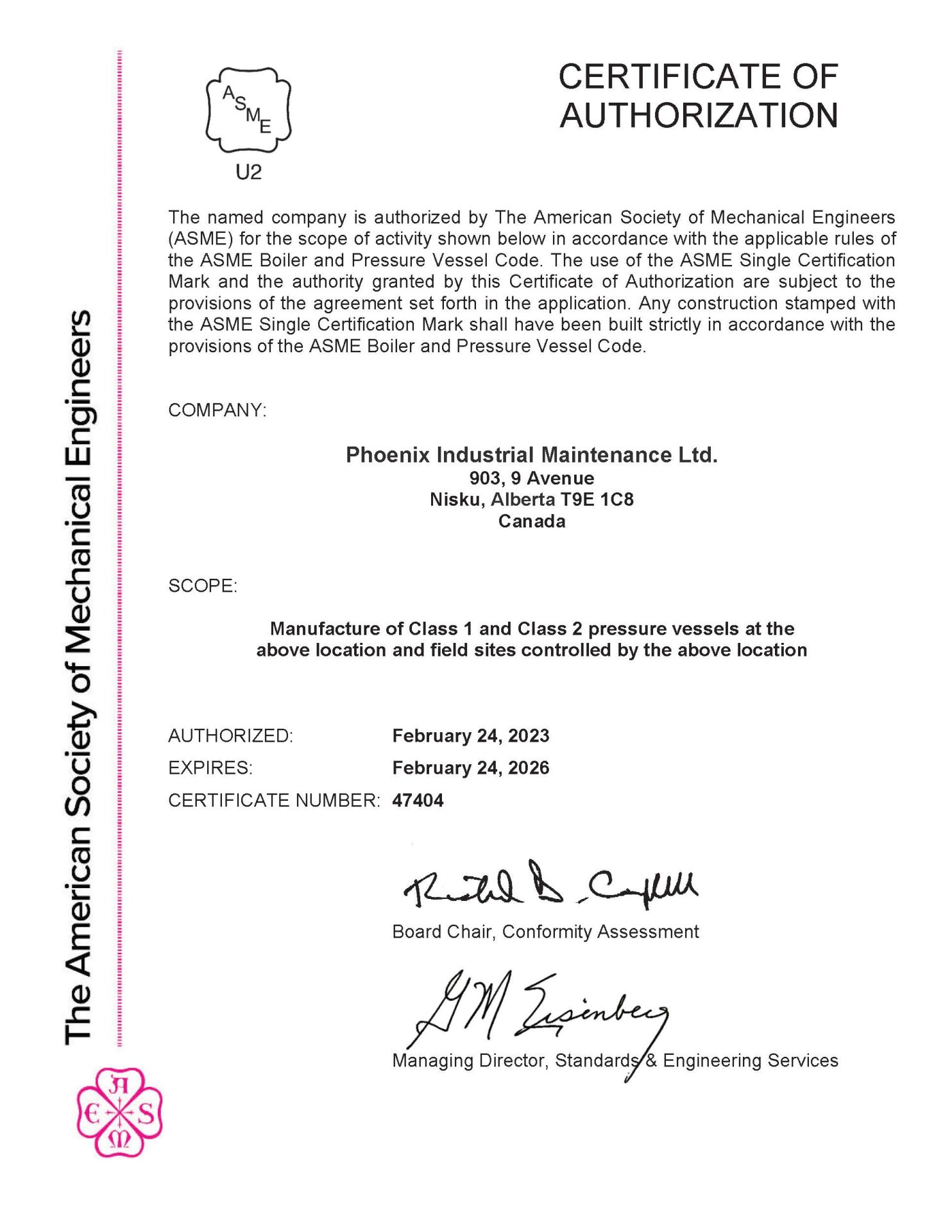

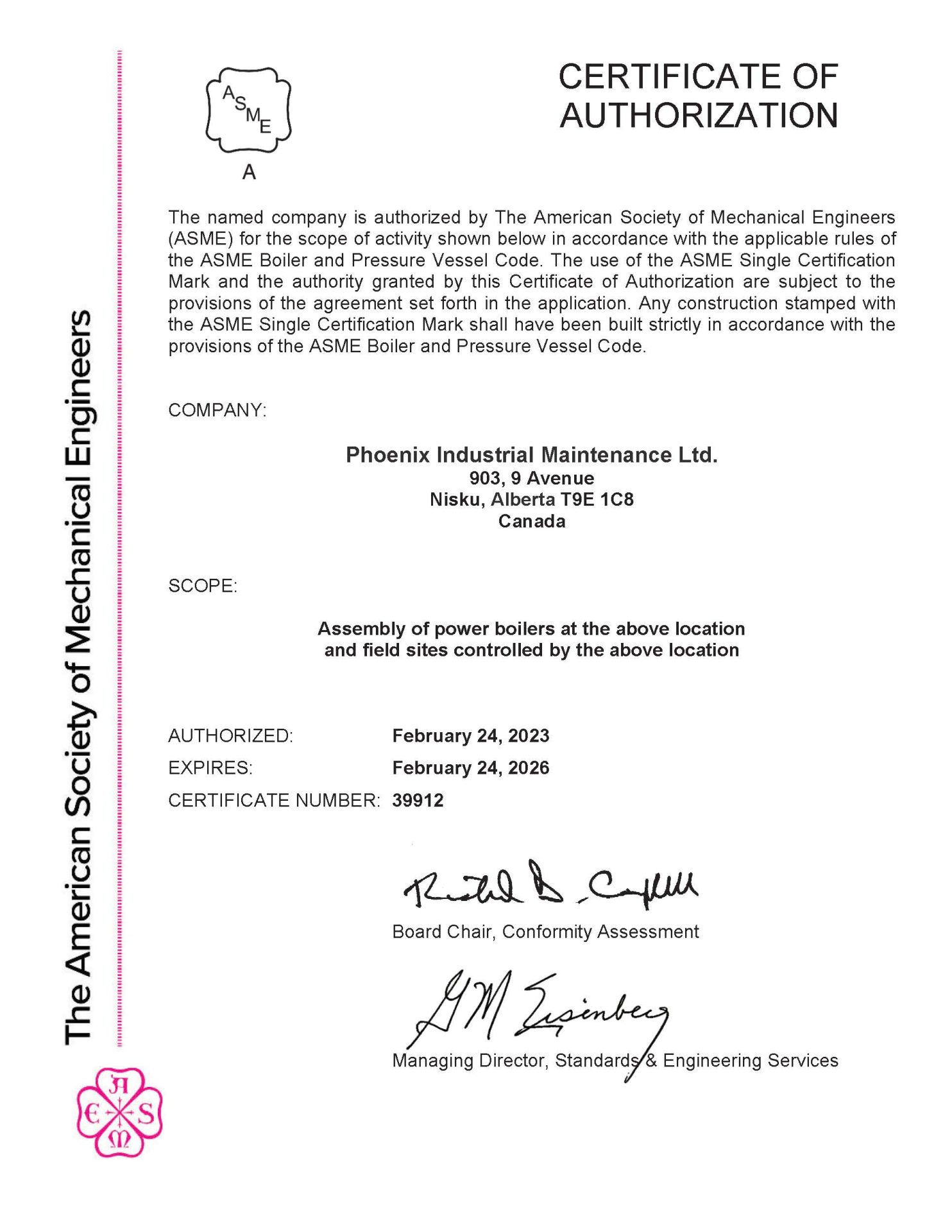

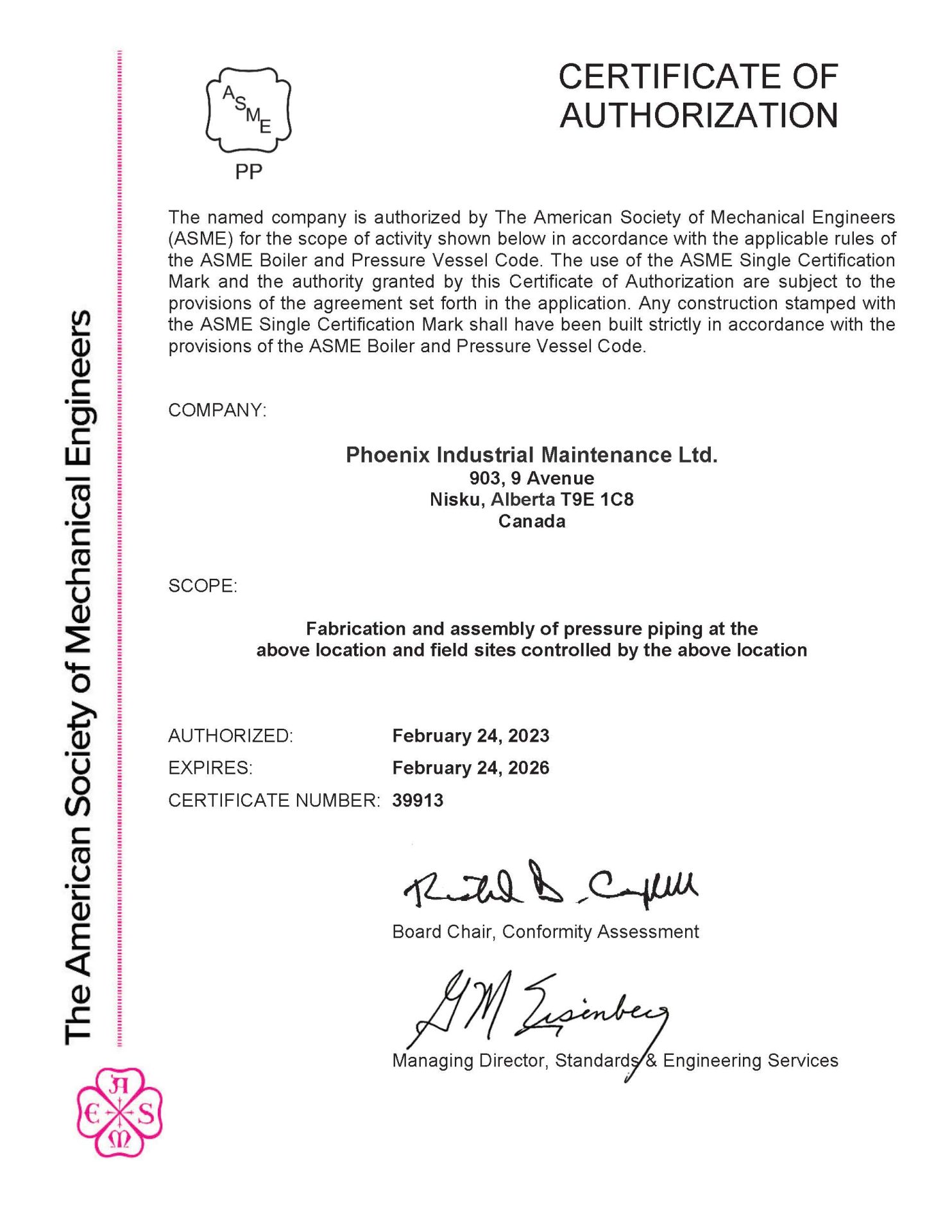

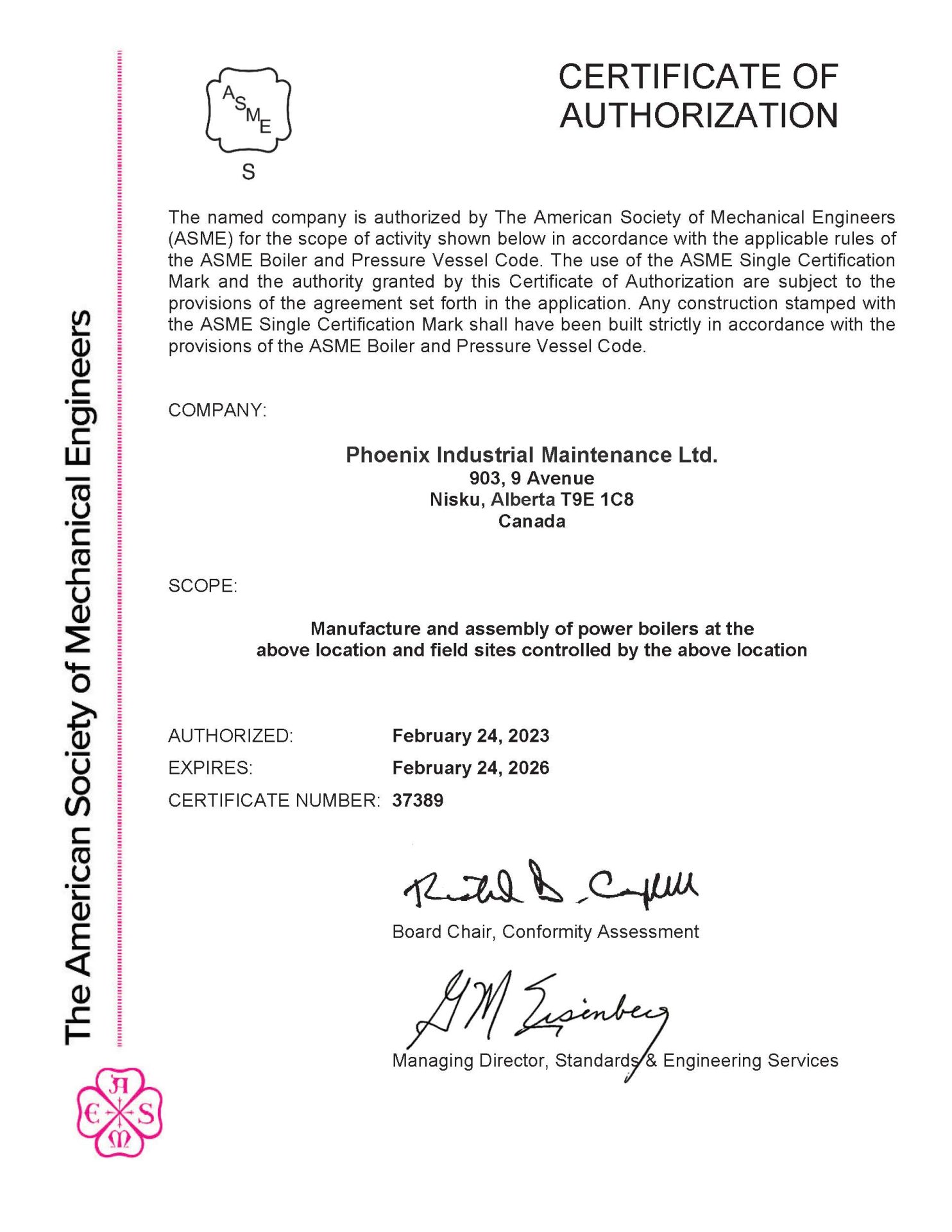

ASME Certifications

- ASME “U Stamp” – Manufacture of Pressure Vessels

- ASME “U2 Stamp” – Manufacture of Class 1 and 2 Pressure Vessels,

- ASME “S Stamp” – Manufacture and Assembly of Power Boilers

- ASME “A Stamp” – Assembly of Power Boilers

- ASME” PP Stamp” – Manufacture and Assembly of Pressure Piping

For Close Toggle Default

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

CSA

- CSA Z662 Steam Pipelines – Construct, Alter, Repair (Shop and Field)

CWB

- CWB-Letter of Validation Fusion Welding of Steel – PHOIN 1

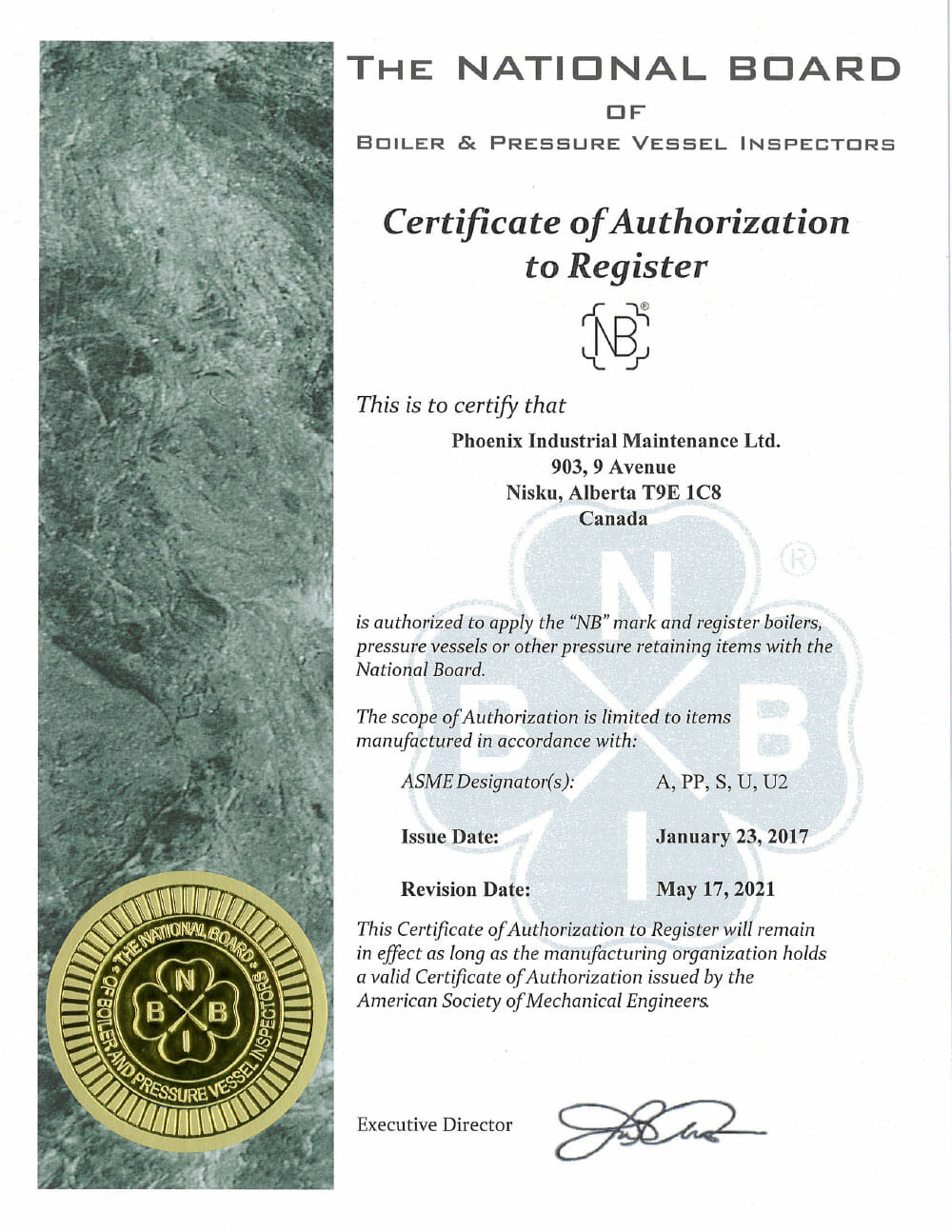

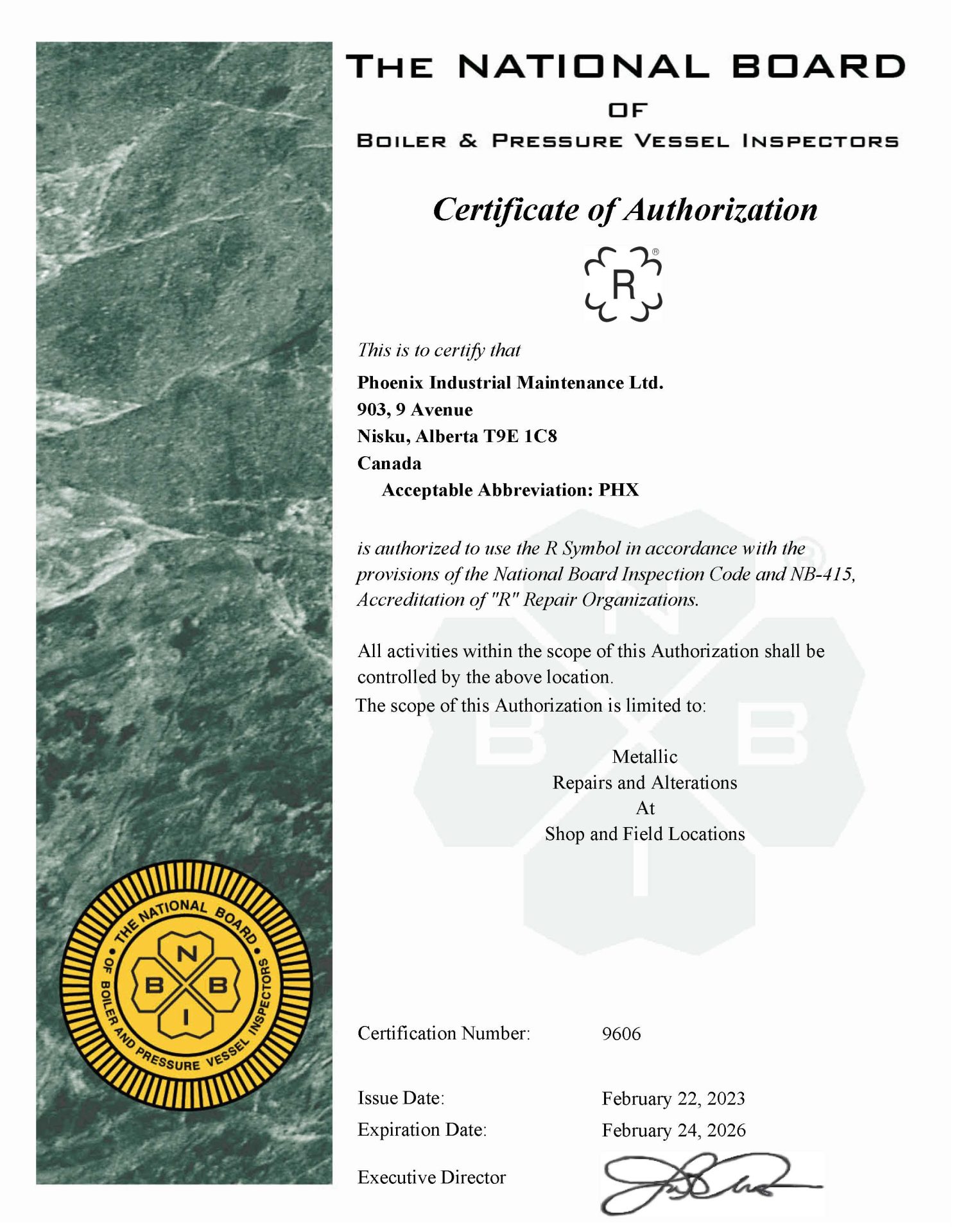

NBBI

- NATIONAL BOARD

- NBIC “NB” Certificate

- NBIC “R” Certificate #9606

Associations

Construction Owners Association of Alberta (COAA)

Canadian Council for Indigenous Business

American Society of Mechanical Engineers (ASME)

Canadian Welding Association

Canadian Welding Bureau (CWB)

National Board of Boiler & Pressure Vessel Inspectors (NBBI)